Biosolids Dewatering

Biosolids Dewatering removes water from biosolids to reduce hauling requirements and directs biosolids to loading stations for the Resource Recovery & Reuse Department.

The treated biosolids from the anaerobic digesters, which is to be used as a fertilizer product, has a solids concentration of approximately two to three percent. That means 97 percent of the fertilizer product is water. Excess water is removed through a dewatering process to generate a spreadable product for land application.

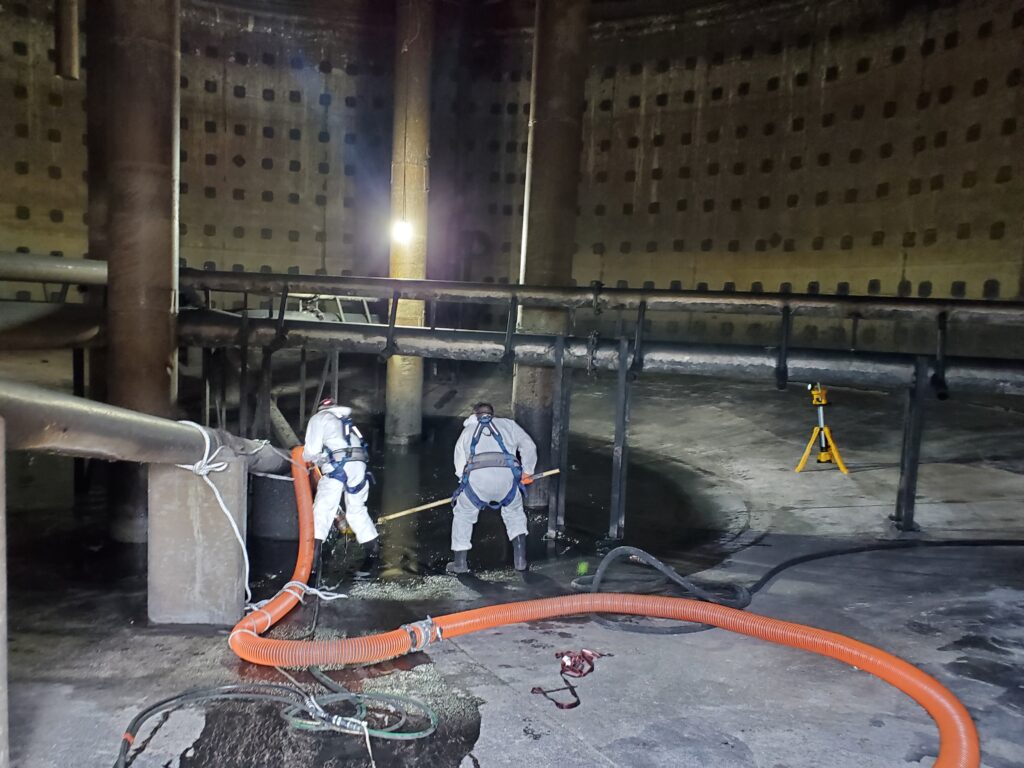

The dewatering processes consist of adding polymer to neutralize charge and bring particles together, followed by equipment designed to apply mechanical force to drive the excess water from the solids. Centrifuges operate by rapidly rotating the sludge in a cylindrical vessel to force the heavier solids to the internal walls of the rotating assembly and the water to its center.

The end product, called “cake”, no longer flows and is instead conveyed to storage tanks for truck loading and transport to farms. Approximately 22 trucks are loaded with biosolids and head to various farms each day.

Sidestream Treatment

Metro uses innovative technologies to accomplish sidestream treatment for the reduction of nutrients prior to returning the dewatering liquid flow to the mainstream.

Robert W. Hite Treatment Facility

Following anaerobic digestion, the digested sludge is treated in the MagPrex process where magnesium chloride is added and the pH increased through aeration-induced carbon dioxide stripping. This process results in struvite (magnesium-ammonium-phosphate) formation in a controlled environment, which reduces the phosphorus leaving the reactor by more than 90 percent and the ammonium leaving the reactor by approximately 10 percent. The MagPrex process also reduces the polymer use in the subsequent centrifuge dewatering process by as much as 25 percent.

Following centrifuge dewatering, the ammonium-rich centrate, or dewatering liquid, flows to the AnitaMox deammonification reactor where more than 50% of the ammonium is converted to nitrate and nitrogen gas, significantly reducing the resulting nitrogen load on the secondary treatment process.

Northern Treatment Plant

At NTP, sidestream treatment is performed as a single mainstream sludge treatment process directly after anaerobic digestion – using the post-aerobic digester (PAD) process. Digester effluent is sent to a special tank that includes jet-aeration mixer nozzles and contains a culture of beneficial microorganisms that are very similar to the secondary process. By aerating the digested sludge , the microorganisms in the PAD tank convert ammonia into nitrate, then convert the nitrate into nitrogen gas. Calcium compounds are added to increase alkalinity for ammonia oxidation and to precipitate phosphorus out of solution.